ELECTRICAL ENCLOSURES HOUSE CRITICAL COMPONENTS that generate heat during operation. Proper air circulation can make or break an electrical enclosure. Inadequate air circulation can lead to isolated temperature accumulation, running the risk of system malfunctions, reduced component lifespan, and compromised reliability.

To select the best cooling solution for an electrical enclosure, consider such factors as the unit’s proximity to operators, whether it will be installed in a temperature-controlled facility, and the type of airflow inside the enclosure. Read on for an overview of electrical enclosure cooling challenges, a review of tools that can be used to simulate and optimize airflow patterns within the enclosure, and considerations for designing electrical enclosures for optimal air circulation.

Electrical enclosure basics and challenges to proper heat dissipation

Electrical enclosures serve as protective housings for power supplies, circuit boards, drives, motors, and electrical components. The enclosures must maintain optimal operating temperatures to operate these components efficiently, avoid the need for costly replacement, and get the longest possible lifespan from expensive equipment.

Unfortunately, as manufacturing floor space has become increasingly limited, companies have begun to install smaller electrical enclosures. This poses serious challenges to the effective air circulation necessary to dissipate the heat generated by electrical components in the enclosure. This dissipated heat needs to either be cooled or carried outside the enclosure to the ambient environment to prevent temperature-related issues like thermal stress, accelerated aging, and potential component failure. Proper air circulation also ensures a uniform distribution of temperature within the enclosure, reducing the likelihood of localized hot spots.

Cooling electrical enclosures maintains the optimal operating temperature and prevents potential damage to electronic components. Common cooling strategies for managing this thermal challenge include incorporating fans that utilize open loop cooling, or using closed loop cooling, such as heat exchangers and air conditioning systems designed specifically for enclosures.

Enclosure air cooling considerations

Before selecting the electrical enclosure cooling solution, begin by evaluating the environment in which the unit will be installed. If you are exhausting heat out of the enclosure in proximity of any operators, install baffling to avoid the air hitting the operators. The solution can also be positioned away from the operator.

Next, determine if the solution is being installed in a temperature controlled facility. This is important, because the heating, ventilation and air conditioning (HVAC) systems cooling the facility must account for heat rejected into the ambient environment; failure to take this into account may cause overheating because the enclosure’s heat becomes rejected into the facility. Working with a mechanical contractor can establish if the heat load inside the enclosure can be exhausted into the facility. In certain scenarios, an air-to-water heat exchanger can be more beneficial, as it rejects heat into the water where a liquid chiller can handle the additional heat load.

Another factor to consider is airflow inside the enclosure. Since enclosures are becoming more densely packed, companies must maintain proper and consistent airflow to prevent hotspots or potential condensation from overcooling.

Use computational fluid dynamics to simulate and optimize enclosure airflow patterns

To ensure that the enclosure cooling solution meets application-specific needs, consider using a computational fluid dynamics (CFD) analysis to simulate and optimize airflow patterns within the enclosure. The tool can be used to identify potential hotspots within the enclosure, verify that temperature distribution within the enclosure is manageable for components, check the potential for pressure pockets between components, and even determine if specific components are being overcooled.

Below are three CFD analysis test scenario examples. The scenarios feature a variable frequency drive (VFD) positioned in front of an air conditioner’s (A/C’s) outlet to show the impact on airflow, because the VFD is the component that would be creating the most heat in an enclosure. The scenarios were designed to examine a common misconception made by cooling solution designers who often mount the most sensitive/highest heat generating components closest to the A/C unit to ensure it is properly cooled, without understanding that this placement will create disturbances in airflow.

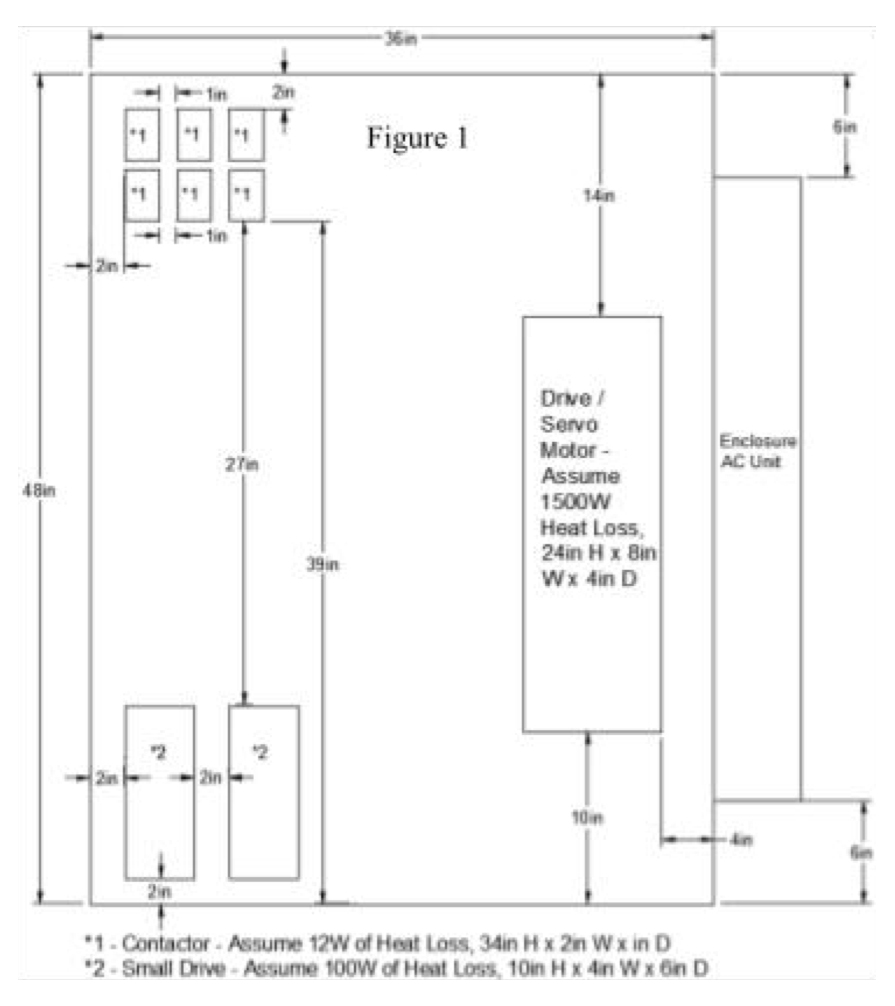

Figure 1 The test scenarios were designed to push the drive deeper into the cabinet for each scenario away from the cold air outlet on the bottom of the AC unit. The other components were mounted in positions to show potential hotspots that could be generated. Drives inside of enclosures typically include an internal fan or heat sink to reject the heat from the drive.

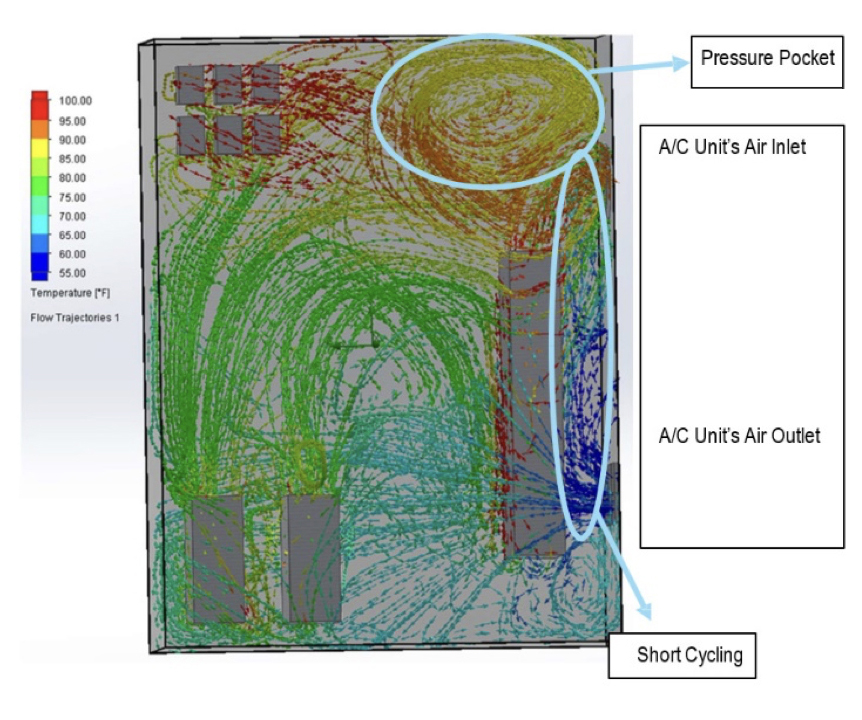

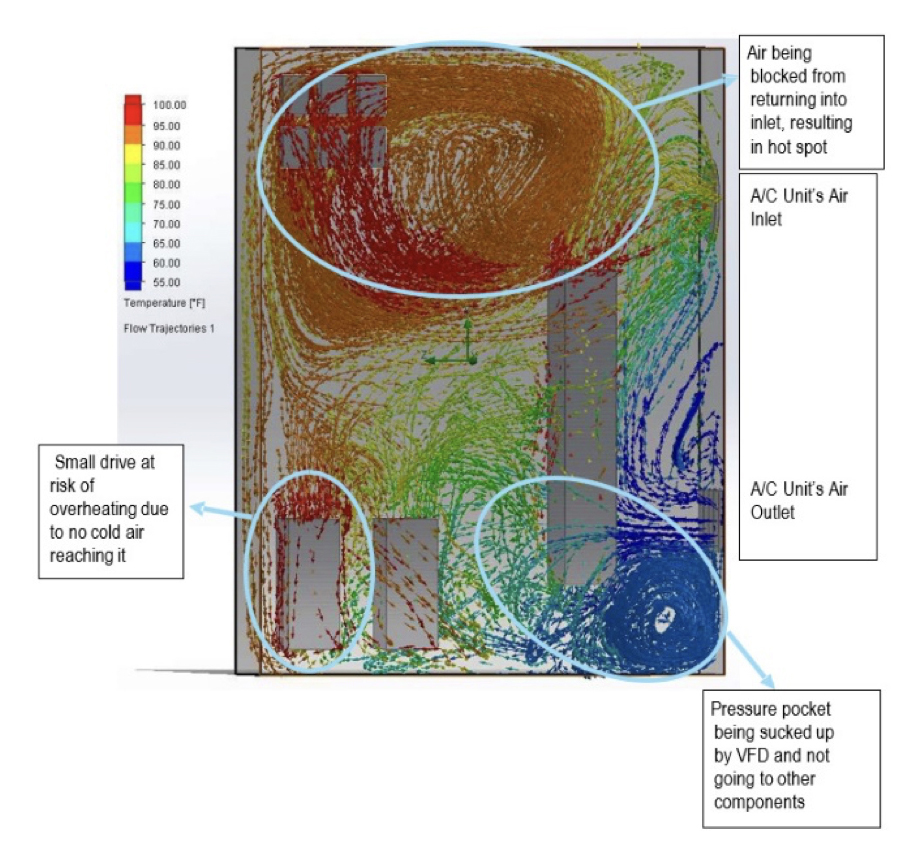

The density of the lines and arrows of airflow paths mean more airflow is traveling in that direction. The colors of the lines are representative of the temperatures of the air travel – blue is the coldest air and red is the hottest air.

In Test Scenario #1, the blockage was 4 inches from the cool air outlet. In this configuration, a majority of the cold air leaving the A/C unit would be blocked by the large drive in front of it, resulting in it cycling right back into the A/C unit’s fan inlet. The cooler air being redirected immediately back into the cooling unit “tricks” the A/C unit into believing setpoint has been reached and will shutoff immediately. Once the heat from the other part of the cabinet rises, the A/C unit will turn on again. The short interval between the A/C turning off and on is referred to as short cycling.

This means that the A/C unit is failing to remove the heat from the cabinet as well as placing a strain on the A/C unit’s compressor for it to turn on and off in consecutive use, which could lead to potential icing inside of the A/C unit’s air outlet. A pressure pocket forms in the top right hand corner of the enclosure due to the drive’s exhaust being sucked directly into the A/C unit’s fan inlet and blocking the airflow path for the hot air to return to be cooled by the A/C unit.

In Test Scenario #2, the blockage was pushed to 8 inches of total distance between the A/C unit’s air outlet and drive. While the unit still risks short cycling with cold air being pushed back into the evaporator fan inlet, increased airflow reaches the other side of the enclosure. A smaller pressure pocket forms in the lower right corner where air is drawn into the large drive’s fan, leading to improper airflow inside the cabinet. The large drive’s fan blocks airflow to the A/C unit’s air inlet, causing a large pressure pocket of hot air to form, which prevents hot air from escaping. This could lead to overheating of the contactors due to insufficient cooling. The two smaller drives in the corner are at risk of overheating, with the left one vulnerable as the right drive takes in cold air before it reaches the left one.