THE WORLD CORROSION ORGANIZATION ESTIMATES the global cost of corrosion at $2.5 trillion (USD) or about 3% of the GDP in most industrialized countries. Therefore, any money saved by preventing corrosion, including the cost of lost productivity because of outages, delays, failures, and litigation; labor; and new equipment to replace failed parts, directly improves profitability.

Consider the petrochemical refining industry where processing equipment, electrical systems, and lighting need protection against pitting, corrosive gases, and water intrusions. In the U.S. alone, the industry’s annual direct cost of corrosion is estimated at $3.7 billion. Of this total, maintenance-related expenses are estimated at $1.8 billion, vessel turn- around expenses at $1.4 billion, and fouling costs are approximately $0.5 billion. In a commodity-driven industry, investment in more effective corrosion control strategies often takes a backseat to across-the-board cost-cutting measures to the detriment of long-term profits, environmental safety and operational productivity.\

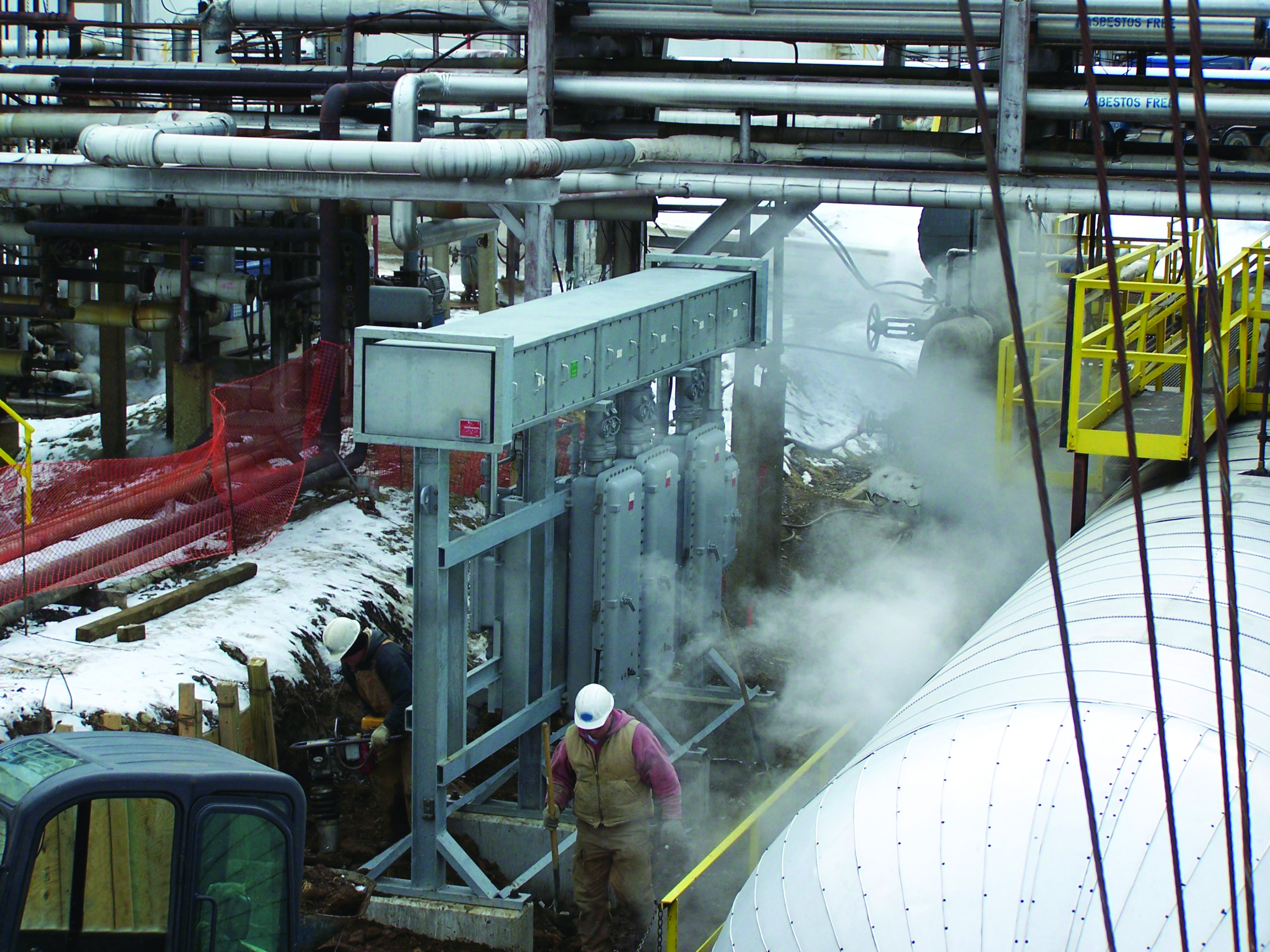

Before

After

When specifying electrical products for harsh environments choosing the right materials to ensure adequate corrosion-resistance is crucial. In offshore oil and gas operations, for example, equipment is under constant exposure to sea-water and salt spray, both of which are highly corrosive due to the autocatalytic action of sodium chloride and other dissolved chlorides. Corrosive substances such as hydrogen sulfide and carbon dioxide also occur naturally in oil and gas fields. Other corrosives that affect a wide range of industries include chlorine, bromine, hydrochloric acid and ammonia.

Iron & Steel Types

Most industrial electrical products worldwide are still made of coated metal. The most commonly used metals are ferrous, taking advantage of iron’s strength, versatility, workability and relative affordability. Unfortunately, with the exception of stainless steel, ferrous products are also the most susceptible to corrosion.

Protective Coatings

Various finishes can be applied to help isolate metallic surfaces from the sur- rounding corrosive environment. The most familiar example is ordinary paint applied to steel to prevent rust. However, there are several other methods including baked enamel, epoxy powder coat and PVC coating. For effective protection, coatings must be applied properly and protected against damage during installation and use. The zinc surface on galvanized steel serves both as a protective coating and, if damaged, a sacrificial anode that will corrode in preference to the exposed steel.

Galvanization and Finishes

Before

After

Galvanization of iron and steel products can greatly improve corrosion-resistance in wet or weather-exposed environments. In particular, galvanized cast iron and non-stainless steel products are often used in wet and weather-exposed locations with the expectation that they can safely remain in service for many years. Yet the same products would likely be unsuitable for direct exposure to corrosive chemicals. A wide variety of liquid and powder coat finishes can be applied to iron and steel products – including galvanized products – to help seal out water, air and corrosive chemicals. Their effectiveness depends on thorough coverage, reliable adhesion and suitable resistance to impact and abrasion in the field. Resistance to chemical degradation is also important. Epoxy powder coat is one example of a finish that provides excellent resilience and strength while remaining impervious to heat and most chemicals.

Galvanization: Providing two forms of protection against rust in a single process

The only effective way to fight rust is to prevent the corrosive processes from the beginning. This is normally done in one of two ways: by adding a barrier i.e., paint, that prevents oxygen and electrolytes such as rainwater from reaching the surface, or by introducing a sacrificial anode, which corrodes preferentially to the iron or steel part. Galvanization provides both of these protection methods simultaneously.

Protective Properties

The galvanizing process creates a metallurgical bond between the zinc coating and the underlying steel or iron. This bond provides much stronger adhesion than any type of paint, including epoxies. The galvanized surface forms in multiple layers, with zinc and iron alloyed in varying ratios. The outer layer of pure zinc is relatively ductile, while the inner layers are progressively harder – harder than steel, in fact. These qualities combine to provide excellent resistance to both impact and abrasion, helping protect against surface damage.

In addition, when left unpainted, zinc exposed to the wetting and drying of weather gradually forms a patina of zinc carbonate over a period of a few months to a year. This patina provides an additional barrier against corrosion. Because it “grows” outward from the surface, this patina is especially effective at protecting edges and corners where paint could be easily damaged.

The most important advantage of galvanizing over paint, however, is the anodic property of zinc in a galvanic couple with iron. If the galvanized coating is damaged – whether by accident or through an intentional action such as cutting or drilling – the zinc will act as a sacrificial anode that corrodes first while protecting the more noble iron or steel.

This protective action will continue until the damage is repaired by applying a zinc-rich paint to the damaged area, for example, or until all the zinc has corroded. Depending on the thickness of the galvanized layer and the corrosiveness of the surrounding atmosphere, the service life, defined as time to first maintenance, can be a couple of decades to a hundred years or more.

Epoxy Powder Coat

Unlike liquid paint, powder coating uses an electrostatic process to apply a finish to metallic parts in a dry state. Once applied, the finish is heat-cured to create a finish that is thicker, tougher, more even on all outer surfaces and edges, and more durable than most paints. This makes epoxy powder coat one of the preferred protection choices for oil and gas, wastewater and other harsh, corrosive industrial applications. To ensure proper adhesion and maximum durability, correct surface preparation and application quality are essential. The goal should be to apply multiple, well-bonded coats to provide optimum resistance against im- pact and abrasion. Components should be periodically inspected for finish damage that exposes the metal underneath to salt spray or other corrosive elements. Epoxy powder coat can also be degraded by UV radiation, so service life may be shortened for products installed in areas exposed to intense direct sunlight.