Vince Miller started Miller Safety Consultants, a veteran owned business in 1999. The goal of the business was to provide cost effective safety consulting, employee training such as: confined space entry, fall protection, electrical safety and provide sales of electrical shock and flash protective equipment and fall protection equipment to businesses in the Washington DC area.

Reliance Industries provided fall protection products and much of the sales and training was on behalf of the supplier. In 2000, the owner decided to retire from his business, and Vince decided to discontinue the fall protection line of his business and concentrate more in the electrical training and products.

Vince had been a distributor for Certified Insulated Products (CIP), a manufacturer of electrical insulated tools and electrical arc flash clothing manufactured by Otex in Rochester, New York. As a distributor, Vince provided sales through his internet website and much through relationships with electrical contractors. His training was a classroom environment and was provided directly to customers but he also taught as a sub-contractor for other safety consulting companies and the Chesapeake Safety Council in Baltimore, Maryland. In 2005, Vince partnered with Vivid Learning Systems in Cascades, Washington to provide online training in safe work practices.

Training in electrical safe work practices is still provided locally in the Washington DC area. The training is based on the Occupational Health and Safety Administration (OSHA) standards and the National Fire Protection Association (NFPA) 70E standard.

Miller Safety Consultants is now a distributor for Cementex USA, Burlington, New Jersey, for insulated tools and equipment and clothing from OTEX Protective, Rochester, New York.

The majority of his sales of products are from the web-based store. Cementex is nationally known for their quality equipment. Otex Protective is becoming more known for their quality clothing. For years, they have manufactured their products under other provider labels. Vince chose to not create his clothing line, but to sell the manufacturer product.

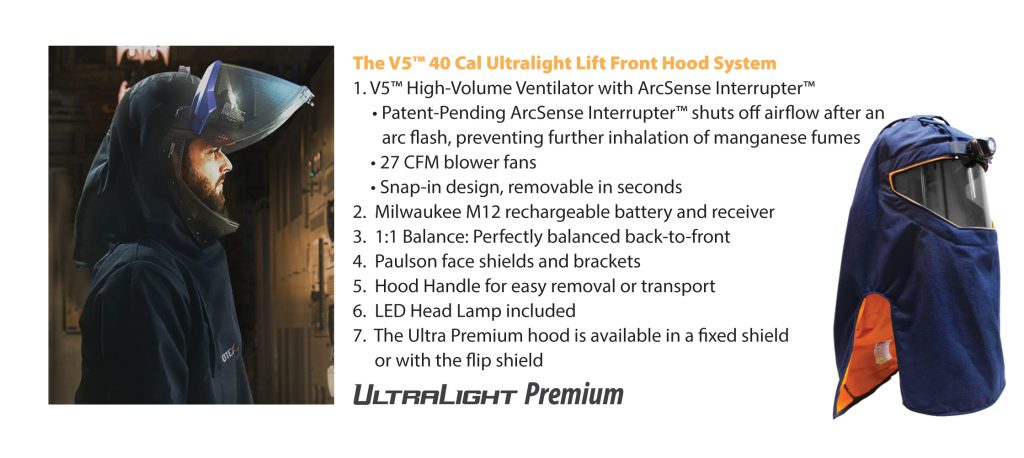

Vince has worked with many electrical company employees to fine tune the clothing to be more comfortable for the user. Working closely with the manufacturer, they have made slight changes in how the cloth pattern was modified to meet final production. An example is the lightweight 40 Calorie vented hood offered by Otex.

The material is of the latest technology. The vented assembly is constructed for balance on the back of the hardhat and the airflow is 27 CFM to prevent fogging of the face shield and provide cooling to the worker. It took over a year to develop the product with the user prior to having the hood “flash tested”. This product is now standard issue with many electrical contractors.

Being a small business and having quality providers has resulted in satisfied customers for Miller Safety Consultants. Being a direct supplier for OTEX Protective, another small business means customized customer needs can be met.