Service and Support

Selecting the proper Power Quality Solution for your application can be tricky. Choose a manufacturer with experienced and dedicated sales representatives, along with available online tools, to help you make the right choice, every time and providing the support when you need it.

Conclusion

Understanding power quality may seem abstract, but as facility managers and equipment owners know, good power quality can boost both productivity and profits, while poor power quality can drain the bottom line due to malfunctioning equipment, downtime, idled workers, energy costs and product scrap.

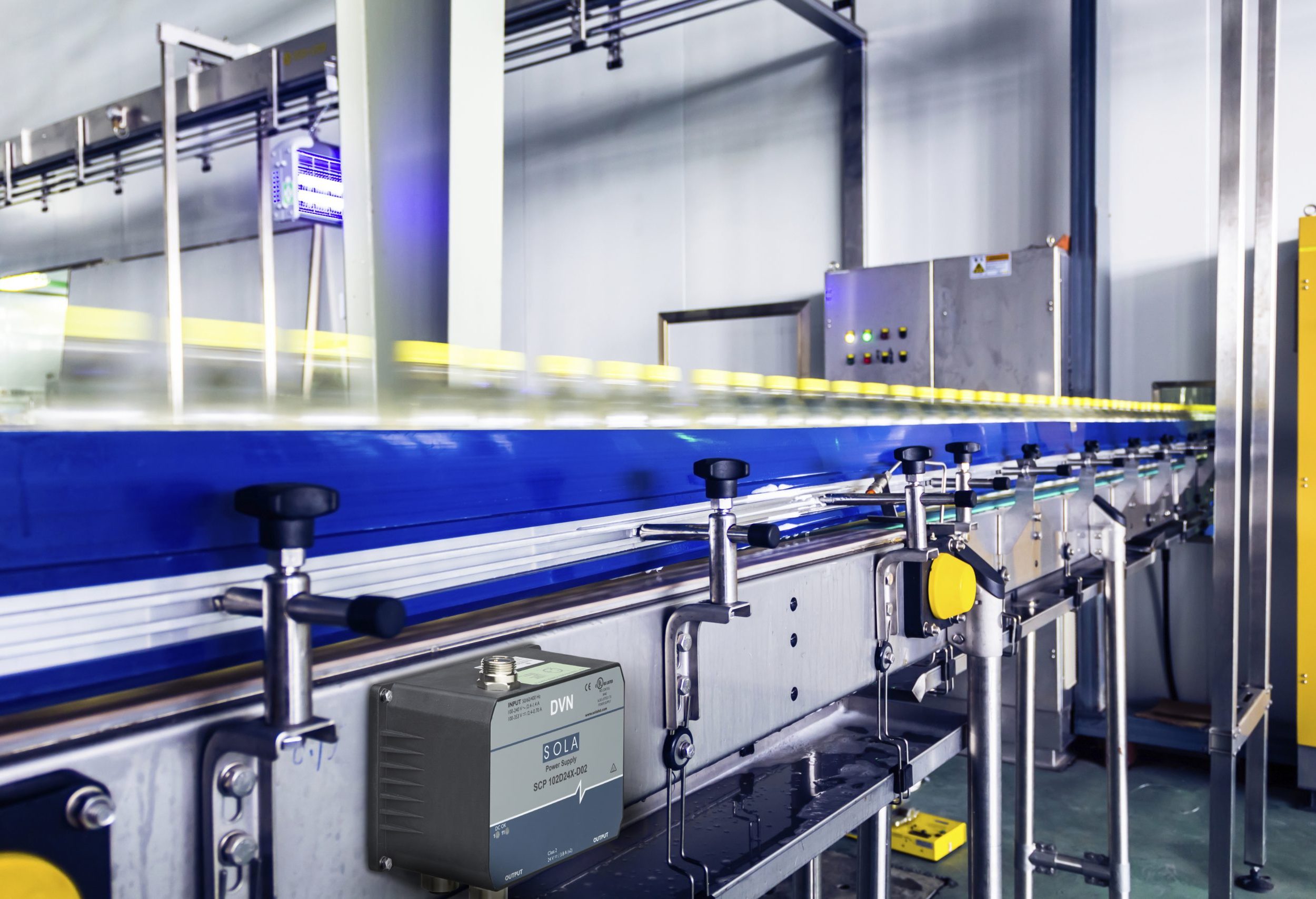

Given the relative costs of power protection devices versus the cost of doing nothing against poor power quality, the devices that improve power quality within industrial and automation settings by OEMs are worth their upfront costs and will continue to pay dividends. Devices that are integrated or bundled within new equipment or control cabinets offer a competitive advantage for the manufacturer’s equipment. For a facility owner, the cost of downtime will hurt revenues and there is a need to protect bottom line.

The users for power quality devices within the MRO, industrial and commercial market spaces all have similar goals. Understanding that there is a potential for a return on your investment to prevent a major shutdown or damage to equipment is important. When a production line or a facility goes down, it typically requires fast attention. However, you can be prepared in advance, or even prevent, with some simple strategies, or applying total power quality solutions, no matter what kind of facility you have.