WE STARTED THE BUSINESS IN 1966 based on more than just making a fair profit. SP Products Inc’s philosophy and dedication to making valid contributions to the industry began with “Econo-Whips” introduced for streamlining and minimizing installation errors in the field.

SP Products is dedicated to developing new labor-saving products & devices working with experienced electrical personnel to enable safer, better, faster installations. Our innovative products have been developed for installations below grade, slab on grade, overhead rough in and wall rough in applications. Our products are UL listed and we are proud to make them in the U.S.A.

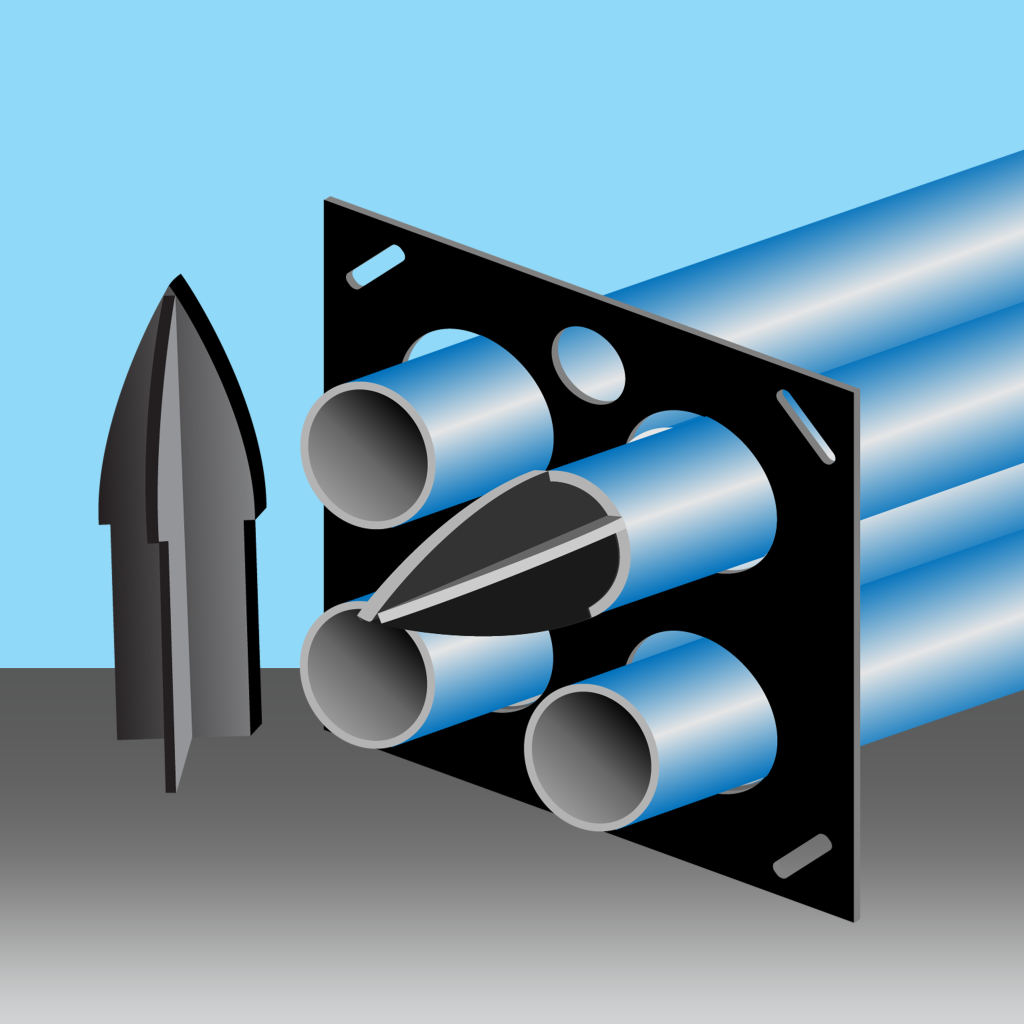

Our QwikDuct HDPE Custom Templates make installing underground conduit runs in trenches safer by keeping workers out of the trench, reducing injury or death. Assembly is done in the pre-fab shop or on site next to trench. Using SP’s QwikDuct Templates allows digging a narrower trench for less excavation, while reducing concrete/slurry, shoring and backfill. QwikDuct is stronger than traditional spacers and chairs, which are clipped together pieces while templates are one piece and rated at 4,000 PSI so assemblies will not collapse. Assemblies up to 250 feet can be lowered from above into the trench with 2 front- loaders or forklifts, saving a huge amount of time & Labor. Templates

can be designed for any configuration up to 5 x 10 feet can and are available in 3/8”, 1⁄2” and 3⁄4” thicknesses. Other options include rebar holes for caging, flow holes for concrete, angled slots to anchor with rebar into the sides of the trench to prevent floating during the pour. Orientation notches can also be added to easily identify proper alignment when setting templates up for assembly. When assembling templates use SP’s Conduit Guides (IP3c) for fast and effortless installation feeding long lengths of PVC through templates while reducing the number of electricians to assemble.

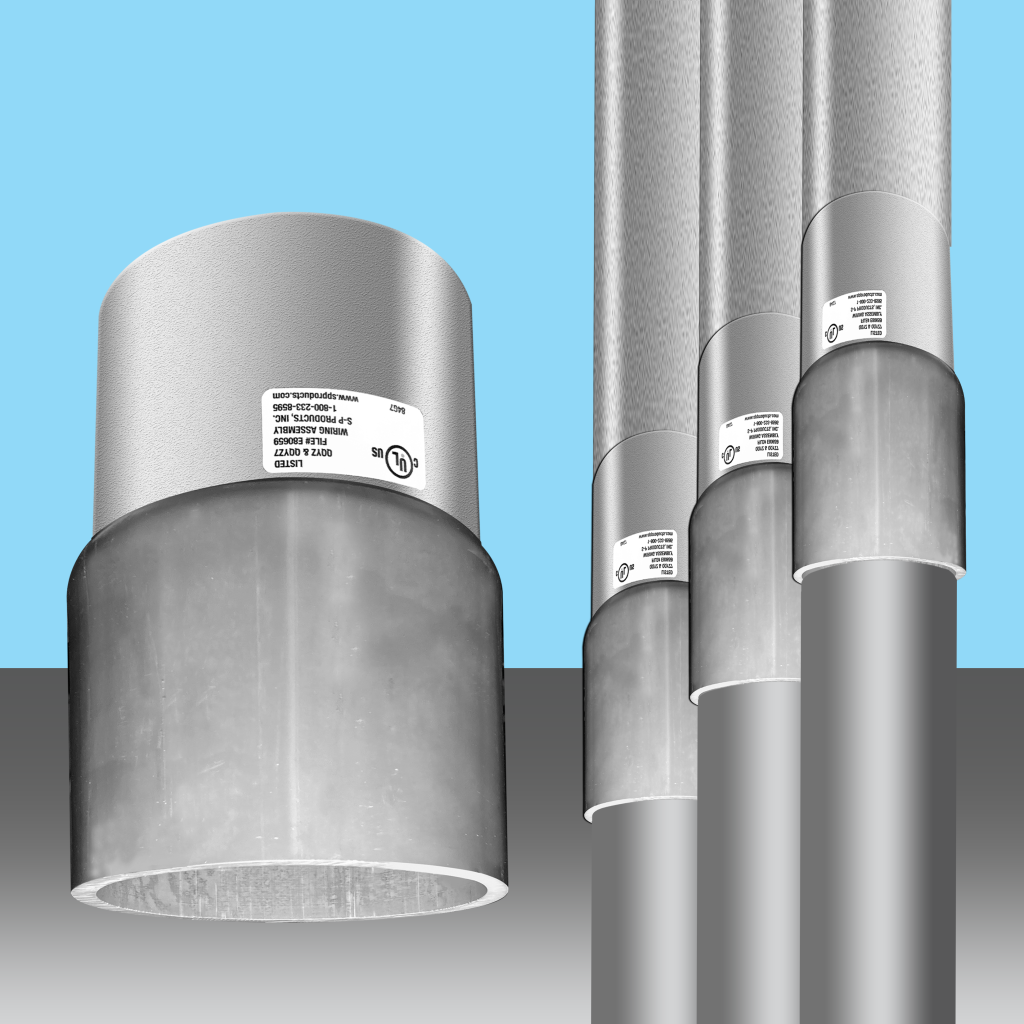

When entering a vault, manhole or building cavity misalignment may be an issue due to templates shifting during the pour. Our Offset Couplings are available from 1⁄2” to 3” offset for schedule 40 PVC, 1⁄2” through 6” and all meet the Mandrel test requirements plus we can add threads to Offsets for ease of installing into equipment. PVC End Bell Adapters (IP14) and Long Slip Couplings for PVC to PVC (IP3f) or PVC to RGD (IP3g) are also available for transitions.Before the slab pour, SP’s EZ Stub-Up support brackets (IP10), make securing 90 degree conduit elbows or conduit sleeves, as a single or multiple conduit applications fast and secure when penetrating the slab.

Transitioning or change overs above the slab is made fast and easy using SP’s transition coupling family (IP13) with, or (IP12) without reaming out the PVC conduit penetrating the slab. Cut schedule 40/80 PVC flush to the slab and ream out with our reaming bits (IP15) and glue and install the appropriate UL Listed Transition coupling to continue the run with desired conduit above the deck.

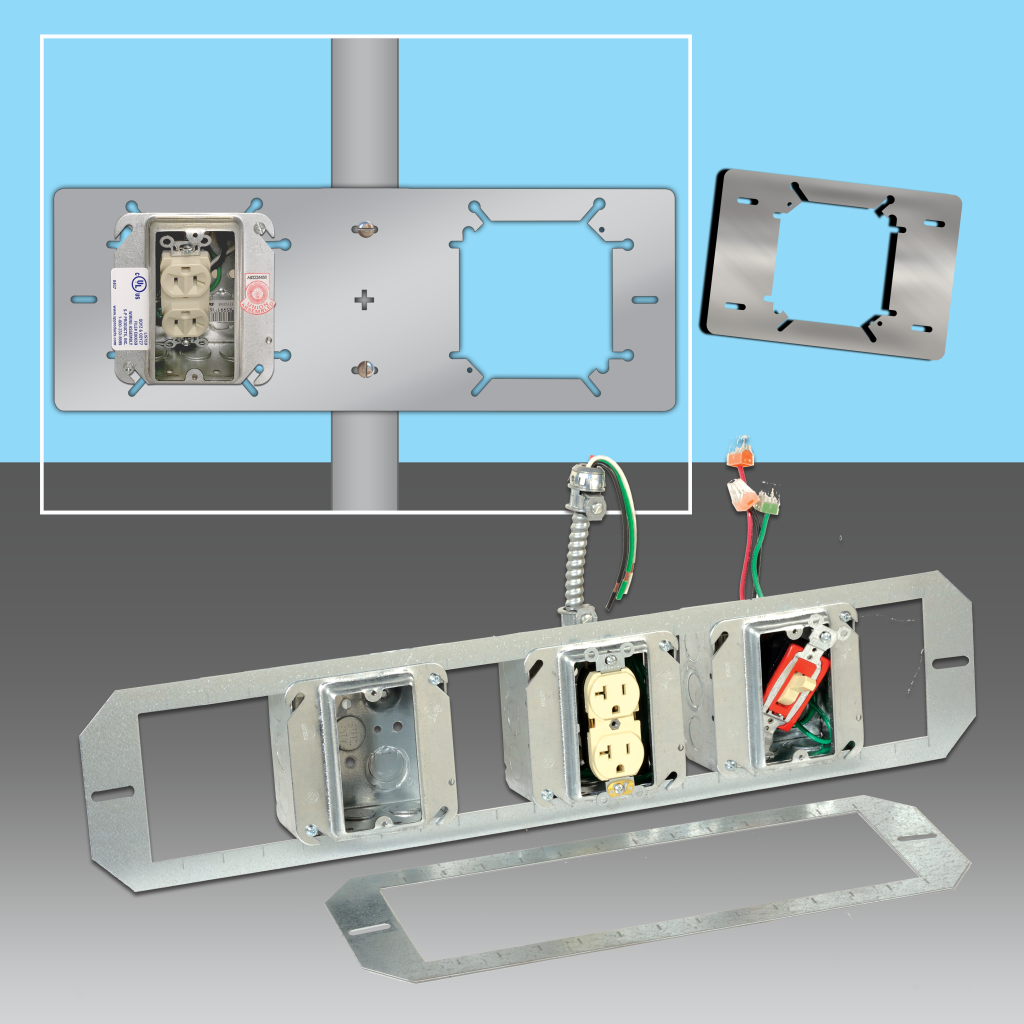

For wall rough applications SP’s product family of box support brackets make pre-fab and installation a breeze with our “Big-O” (IP26), indented or flat brackets. Elongated installation holes, 1 at each end of bracket, allow for sliding bracket left or right for alignment.

We also offer our Flat Fixed Position (IP28) box support product, for 1, 2, 3 or 4 boxes made of 16 gauge galvanized steel with teardrop openings for attaching boxes without removing screws. The single gang version can be mounted on left or right stud applications.

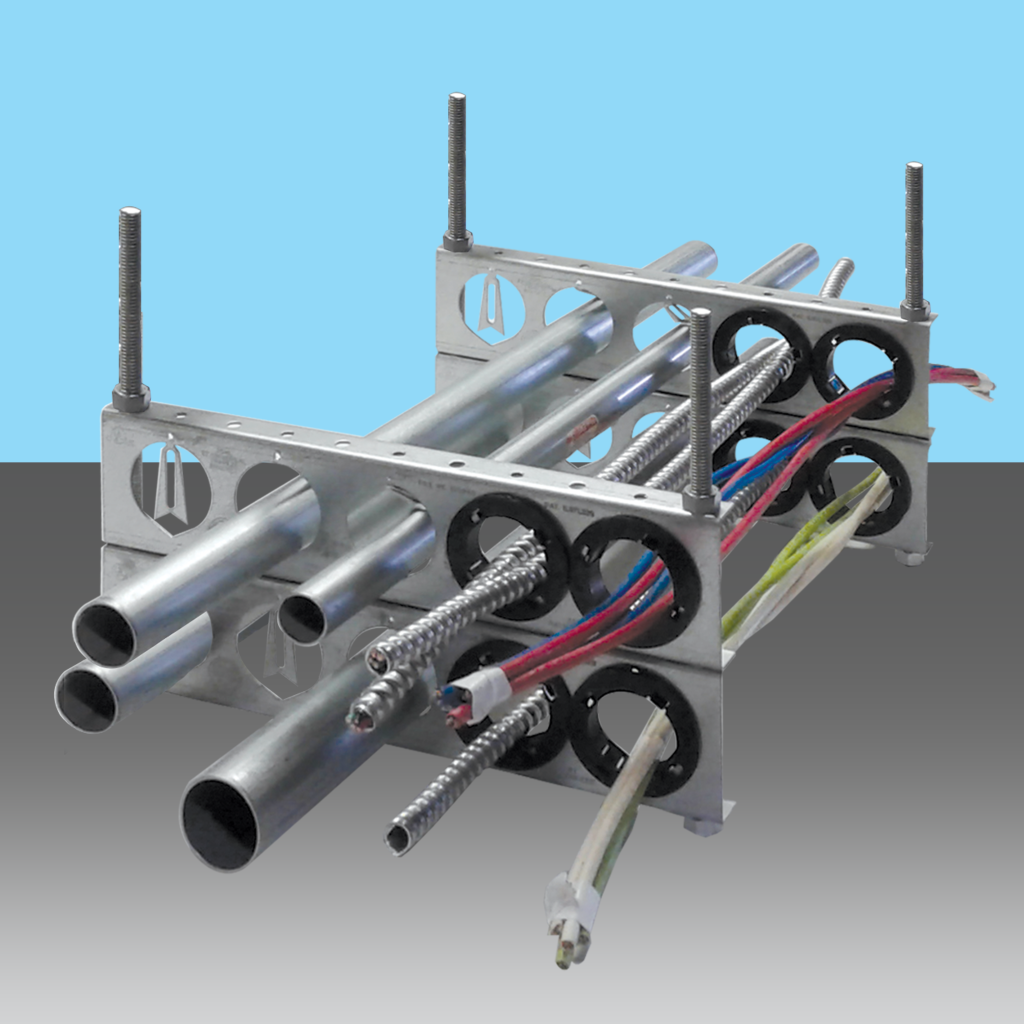

Solutions for overhead rough in applications includes SP’s family of box support plates (IP6-8) can support multiple conduits by a single threaded rod eliminating additional drops and clamps by supporting conduit entering all sides of the box as well as thru the back of the box as your “First Means of Support”. Our Trapeze Bracket feed through family (IP11) of products are available in several configurations and come in lengths of 1 foot increments up to a 6 foot piece. Tabs built into the openings secure the conduit in place or when stacking the Trapeze to create a well-organized, evenly spaced professional looking installations.

Our goal is to take care for our country, industry and electrical personnel by encouraging everyone to buy and install MADE in U.S.A. innovative products for Safer-Better-Faster jobs and that provide opportunities for fair compensation for current and future generations of workers in this country.

We develop and promote products that accomplish these goals and are proud to be the electrician’s friend by providing them with the satisfaction of making a valuable contribution to the Electrical industry and receiving fair compensation for their innovative ideas.

SP Products provides labor saving products and devices to help ease and streamline your electrical construction projects.