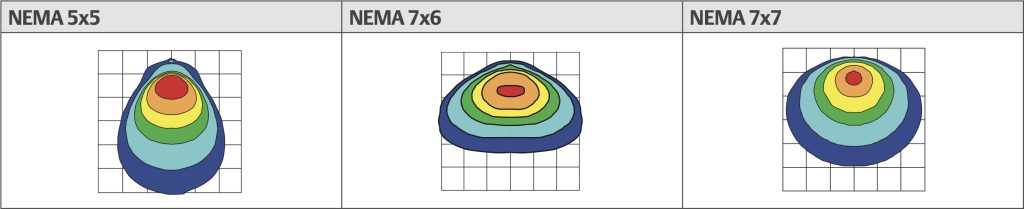

Flood lights are classified by the National Electrical Manufacturers’ Association (NEMA). The NEMA Type specifies how wide or narrow the light is projected out of a flood light. This light distribution is also referred to as beam spread or beam pattern. Typically, the greater the distance between the flood light and the ground or the object being illuminated, the narrower the beam.

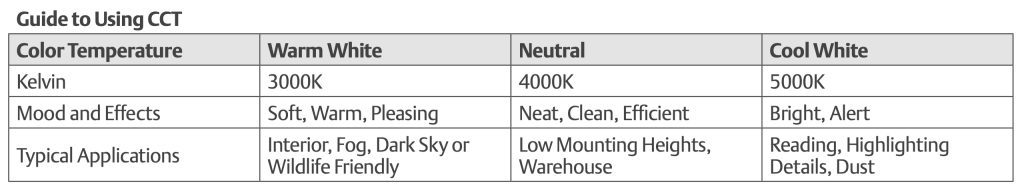

Color Temperatures

Correlated Color Temperature (CCT) refers to the color appearance or the look and feel of the light source. The cooler or crisper the appearance of a light source means the higher the CCT measured in Kelvin (K). Many LED luminaires offer more than one color temperature to suit application needs and customer preferences.

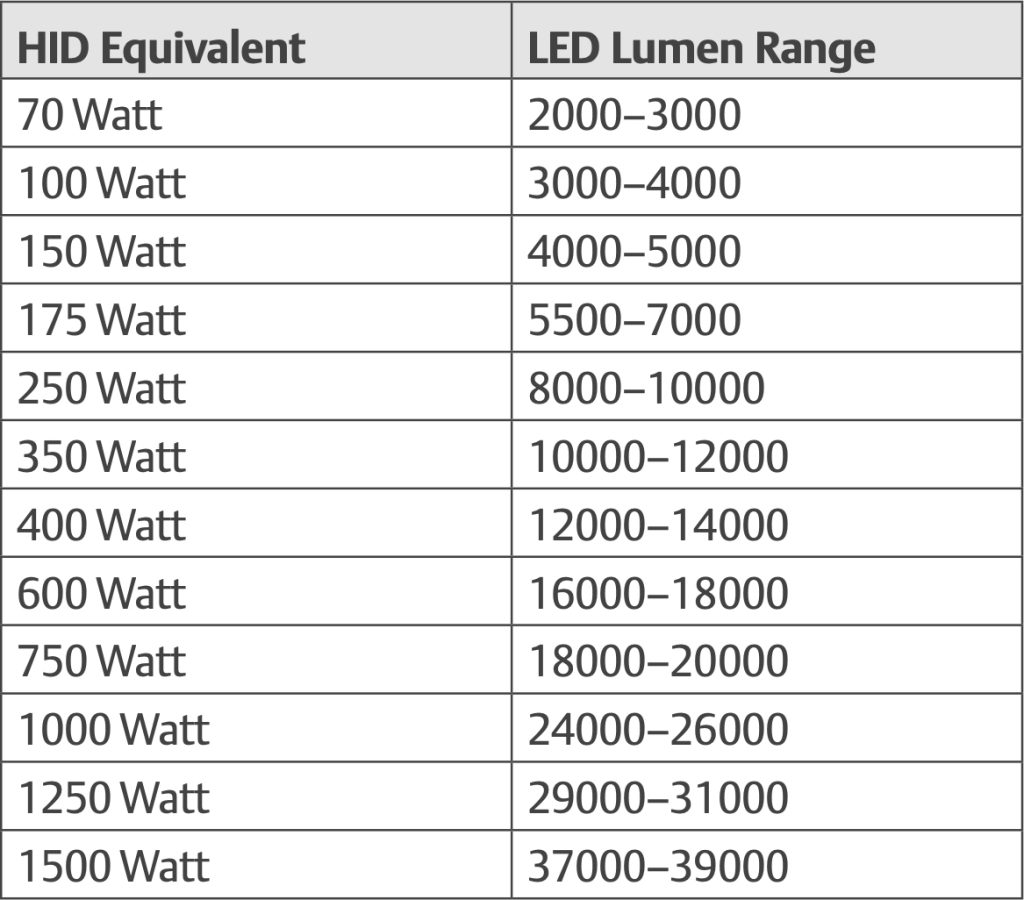

Lumen Level

Because LED luminaires are more efficient than their HID predecessors, a watt for watt replacement would yield significantly higher than desired light levels. Generally, an LED equivalent luminaire produces the same light with 1/3 to 1/2 the energy consumption of HID. Since mounting height, luminaire beam pattern, and overall lighting conditions can all affect perceived illuminance levels, it is always best to request a lighting simulation and a luminaire sample (See chart below).

A concept that may impact lumen levels is “perceived brightness”. The human eye has two types of photoreceptors: cones, which are active in brighter light levels, and rods, which take over in darker conditions. Commercial photometry measurements are based on photopic luminous efficiency, which only involves the cones. However, recent research shows that a white light source is perceptually and functionally brighter than its High Intensity Discharge (HID) equivalent, especially in a dimly lit application, due to the difference in the spectral power distribution of these light sources. Unfortunately, no universal standard exists today to convert traditional HID measurements to their LED counterparts.

Luminaire System Life

Industrial-grade LED luminaires provide energy efficient and environmentally friendly, functionally equivalent, high quality white light with better visibility, no startup delay, no degradation in lighting quality due to on/off cycles, and no end-of-life cycling. Most engineers understand that these are benefits to switching to LED lighting. Quantifying these benefits and determining total cost of ownership, however, can be difficult due to the lack of an IES standard defining luminaire life.

While standards exist for reporting LED depreciation, no accepted standard exists for luminaire life. Manufacturers use a variety of terms to describe projected LED life. Here are a few of them and their accepted definitions:

- LM-80 Testing Standard: The IES LM-80 standard specifies a testing method for evaluating the useful life of an LED package or array. It requires at least 6,000 hours of actual LED operation, with lumen output measured and reported every 1,000 hours. These results can be used to interpolate the lifetime of an LED source within a system using the in- situ LED source case temperature.

- L70 Reported Lumen Maintenance: L70 is the time it takes for an LED’s lumen output to depreciate to 70 percent of its original output. L70 is extrapolated per the calculator provided in IES TM-21, factoring in both application drive current and LED junction temperature. The standard limits reported lifespan to 6 times the number of LM-80 test hours, so that a 10,000 hour test can yield, at most, a 60,000 hour rating.

- L70 Calculated Lumen Maintenance: The TM-21 calculator allows manufacturers to calculate an estimated lumen maintenance beyond the 6 times rule. Although this can be useful for evaluating LED performance, lifetime values that exceed the 6 times multiplier are considered high risk.

Economic Life

TM-21 outlines a standard calculation method to predict future lumen depreciation using LM-80 data. TM-21 assesses lumen maintenance, but not the performance of a complete luminaire system under real world conditions. To determine expected economic life, you must evaluate the entire system, including projected LED driver life, power line surge and noise immunity, light engine performance under thermal shock, long term gasket endurance against moisture ingress, and corrosion resistance. One key factor is operating temperature, which can vary considerably with changing daily and seasonal temperatures. When operating within ambient temperature ratings, the average temperature of the environment over time provides a suitable approximation for predicting luminaire life.

Conclusion

Heavy industrial environments like manufacturing plants and production facilities provide some of the biggest challenges for LED lighting systems. Excessive heat, moisture, vibration, dust and power fluctuations caused by harsh production processes can contribute to premature LED failure, eliminating potential maintenance and safety benefits. These demanding environments require industrial-grade LED fixtures that deliver illumination without incident.