HEATING CABLES, REFERRED TO AS HEAT TRACE CABLES, PIPE TRACING, OR HEAT TAPE, ARE COMMONLY MANUFACTURED IN TWO BASIC FORMATS – constant wattage cables, which generate a specific amount of heat, based on the resistance of the wire to the power supplied, and self-regulating heat cables, which generate a varied amount of heat when energized, based on the temperature that surrounds it. However they operate, they all work to achieve the same result, radiating heat and warming up the area around it.

Heating cables are used in a multitude of applications, from pipe freeze protection, to snow melting on a sidewalk or driveway. From preventing ice dams on roofs, to indoor floor warming when installed under tile, stone or engineered vinyl flooring. Heating cables are also used in a wide variety of industrial applications, from basic freeze protection to more advanced temperature and viscosity maintenance operations, with specific heat requirements. Industrial heating cables will not be addressed in this article.

As mentioned earlier, there are two primary types of heating cables:

- Constant Wattage Heating Cable is the most basic of the two. This is a fixed resistance heater, that when energized produces a specific output, based on the design length of the cable. These types of fixed length cables operate at 100% capacity when power is applied, and normally require a thermostat to operate the cable and ensure efficient, effective operation. Constant wattage cable cannot be overlapped, as this could cause them to overheat. They offer the advantage of being inexpensive, but are limited to specific lengths and wattage densities, making them less versatile than self-regulating cables. Constant wattage cable can be used on indoor and outdoor water supply lines that are subject to freezing temperatures, and on residential asphalt shingled roofing. They provide an economical option for heating pipes in crawlspaces, cottages, barns and outbuildings that are unheated. Constant wattage cable is also the primary heater used for embedded applications like snow melting and floor warming, where power availability and predictable load may be a consideration.

- Self-Regulating heating cables are designed to overcome some of the constraints of constant wattage cables. With this type of cable, the heating element is a carbon-black polymer, extruded over two buss wires, which when energized, produces heat ouput, based on the temperature that surrounds it. Power output is increased as temperature decreases, and conversely, as temperatures rise, the power is reduced. In an ambient operation, such as freeze protection or roof and gutter deicing, no thermostat is required because they automatically vary their heat output based on changes in the surrounding temperature. Unlike resistive heating cables, self-regulating heaters can be cut to any length, without impacting the operation of the cable in any way. Designed for industrial, commercial and residential applications, they can be used on metal or plastic pipes in a variety of applications, as well as on all types of roofing.

Pipe Protection with Heating Cables

Consider this: a gallon of water, when frozen, will expand to a volume 9% greater than the original gallon. So it is no surprise that a water filled, frozen pipe will swell up and crack.

A bulge or crack in a pipe with ice seeping out is a clear indication of a burst pipe. More often than not, a pipe may look fine and the homeowner may not see the small fractures caused by freezing water and ice expansion. Unfortunately, once the ice inside a frozen pipe begins to melt and water seeps out, it is already too late. Depending on the how long it goes unnoticed, total cleanup costs from a broken supply line can soar to tens of thousands of dollars. State Farm Insurance estimates the average insurance claim for water damage from frozen pipes is approximately $15,000.

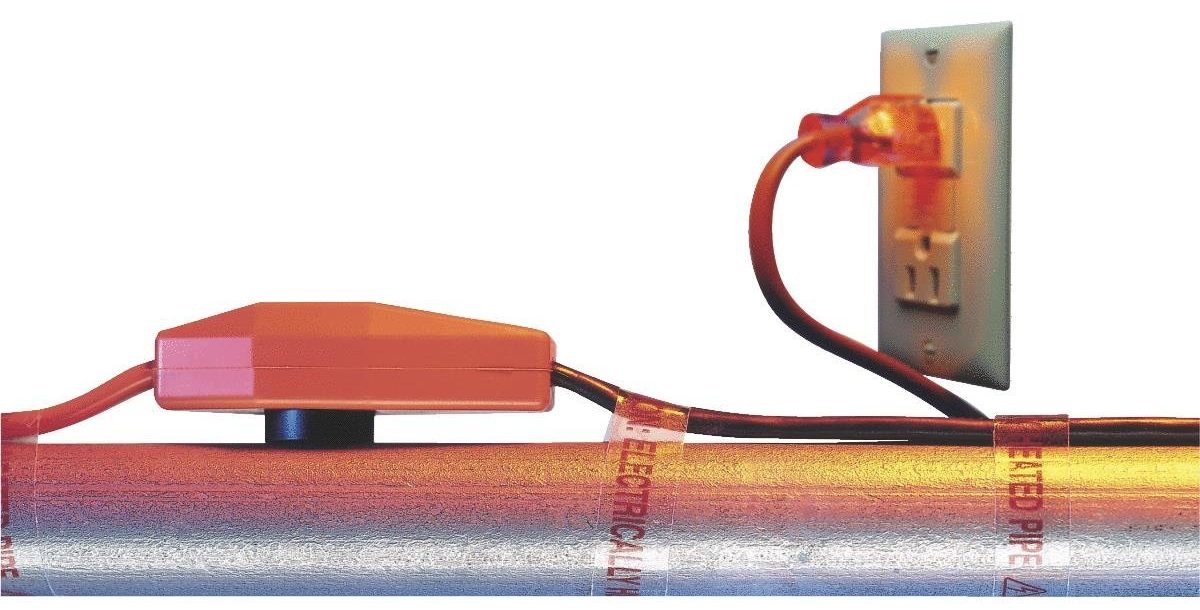

If a building owner knows that a certain part of a structure with active water pipes may experience temperatures below freezing, the smart solution is to install a heating cable. The integrated thermostat on the resistance cables, or a separate ambient-sensing thermostat on self-regulating heaters, ensures the system is automatically turned “on” when temperatures drop below freezing providing the needed level of heat to keep the pipes from freezing. The thermostat provides automatic control of the system so it saves energy by powering the cable only when required. For the system to work effectively, pipe insulation must be installed over the cable to help retain heat. In addition, plastic pipes can be wrapped in aluminum foil so the heat is dissipated evenly over the pipe.

Once installed on a pipe, heating cables should provide protection on your pipes for years require no more maintenance than routine system integrity monitoring — even when temperatures drop as low as -40°F (-40°C).

Preventing Ice Dams with Heating Cables

An ice dam is a formation of ice that appears at the eaves of a roof during extended periods of snow, cold weather, and the freeze-thaw cycles that take place during the winter. Ice dams form when snow accumulation on a roof, above the heated part of a building, melts and flows toward the unheated section – over the eaves, in gutters and downspouts, integral roof drains and scuppers – where it re-freezes, and subsequently accumulates, creating a dam that traps water in a pool. As water takes the path of least resistance, eventually melt water will force its way back up and underneath roof shingles, flashings and drip edge, resulting in leaks and extensive damage to ceilings, floors and behind walls. Repairing a roof is expensive. Even a minor repair as small as a couple of square feet typically costs $1,000 or more. Larger repairs can costs thousands more.

Again, a popular and economical solution to ice dams are heating cables. By preventing ice dam formation along roof edges, in gutters, drains and downspouts, the cables create a path for melted water from the roof to flow into the gutters and downspouts, and on to the ground, preventing ice dams from forming. An automatic controller, available as an accessory, makes operation more energy efficient. When driven by an automated controller, the system is turned “on” when temperatures are below 38°F (3°C) and there is a presence of water on the sensor’s surface. Both conditions must exist for the system to turn “on”, and when the temperature rises above 48°F (9°C), or water is no longer sensed, the controller turns the system off.