ARC FLASH INCIDENTS are of major concern for personnel working with energized equipment. When first adopted by OSHA in 20061, the arc flash Personal Protective Equipment (PPE) worn by these personnel was often hot, uncomfortable, and cumbersome. Innovations in arc flash PPE, however, are maintaining and even increasing user safety while also improving users’ experience of comfort and visibility. Improved ventilation systems and the addition of hi-calorie lift front face shields help to reduce the cumbersome nature of PPE while keeping personnel safer than ever on the job.

Arc Flash Basics

Arc flash incidents can occur in energized equipment due to a number of causes: inadequate safe work practices, faulty insulation, improper grounding, loose connections, defective parts, ground faults in equipment, unguarded live parts, or even small animal incursion. Regardless of the cause, and though rare, arc flash incidents can be very hazardous to personnel working in energized environments, averaging 30,000 incidents every year according the Industrial Safety and Hygiene News 2 3.

During an arc flash event, the extreme heat generated by the flash can ignite clothing and cause burns. Depending on conditions, a blast or explosion may occur, leading to further harm. Proper clothing is required to protect personnel working within arc flash boundaries; while proper clothing resists heat and burns cleanly away, helping to protect wearers’ skin, improper attire can melt, causing clothed areas to be burned even more severely than just exposed skin. What’s more, arc flashes can lead to UV damage to eyes, hearing loss, extreme pressure on the body, and exposure to toxic fumes.

PPE Helps Prevent Arc Flash Injuries

Personal Protective Equipment specially designed for arc flash hazard areas can protect workers who are exposed to arc flash events, regardless of their cause. Properly designed PPE takes time to burn cleanly away from the body, thus reducing the likelihood and severity of skin surface burns to personnel. This, in turn, increases incident survivability and eliminates the hazards of melting clothing.

Arc flash PPE is regulated to ensure personnel safety. NFPA 70E® Article 130 – Work involving Electrical Hazards – says, “Employees exposed to electrical hazards when the risk associated with that hazard is not adequately reduced by the applicable electrical installation requirements shall be provided with, and shall use, protective equipment that is designed and constructed for the specific part of the body to be protected and for the work to be performed.”

These regulations state that when in use, arc rated clothing must both cover all ignitable clothing and allow for movement and visibility. The type of PPE required varies by the possible severity of an arc flash event, and thus by voltages of the energized equipment; in highly energized equipment where arc flash events may be severe, hoods and face shields are particularly important for protecting workers heads and faces from burns and UV light damage. These hoods must cover the wearer’s entire neck, while the face shield must wrap around to protect the face, chin, forehead, ears and neck. These hoods and face shields can be very hot and cumbersome, and can be inconvenient to put on and remove as needed during work and breaks or consultations.

Innovations in Hood and Face Shield Technology

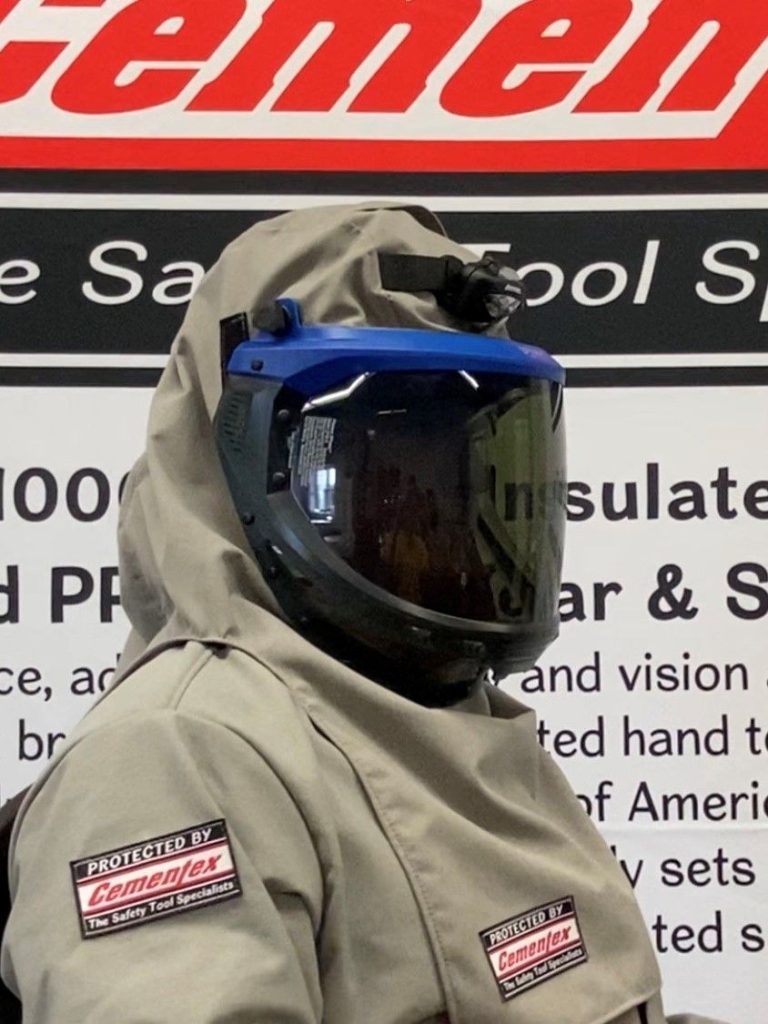

Two innovations in arc flash PPE technology, specifically for hoods and face shields, can help to improve comfort and ease of use in hazardous arc flash environments. These improvements are a ventilation system throughout the PPE suit, and a lift-front face shield integrated into the hood.

The Cementex ventilation system features a durable Kydex™ shell and runs on AA batteries for 6 hours, reaching thirty five CFM.

The ventilation system improves comfort by increasing the amount of overall oxygen flowing suit what’s more, on the extremely hot days the airflow assists in cooling workers’ skin and thus extending time between water breaks and reducing the risk of overheating.

The other major innovation is in the introduction of lift-front face shields integrated into arc flash PPE hoods. Take, for example, the lift-front face shields for the hoods in the Cementex Ultralight Series of Arch Flash PPE. The lift-front hoods provide a larger viewing area and provides personnel (who move out of the Arc Flash Boundary) with the ability to lift the face shield. By enhancing the area of view to see potential hazards and users’ peripheral vision, the new lift-front hood design helps to minimize accidental contact with energized, hazardous conductors. Outside the arc flash boundary with the face shield safely lifted, the personnel can consult with supervisors or coworkers, drink water, or allow greater airflow while taking a break without needing to remove the entire hood. Afterwards, it is simple to pull the face shield back down, return to the work zone, and continue working while adequately protected from arc flash hazards in a timely manner.

Cementex’s lift front hoods remain compatible with its innovative hood ventilation system, thus ensuring the greatest possible safety of personnel in environment around energized equipment.

Any worker who is not diligent in their safety practices could fail to replace the hood to its protective configuration. As a result, retraining personnel to build up habits of securely latching the face shield before entering the arc flash boundary is important to ensuring the greatest possible safety.

Cementex PPE hoods are unique within the Arc Flash Protective Equipment landscape, as the hood completely covers users and is worn over a hard hat, with a headlight available on the top. This hood design enables the use of the ventilation system and provides greater overall protection to users. The lift-front face shield design enhances these innovative hoods even further.

Arc Flash PPE is Critical to Keeping Personnel Safe

Arc flash PPE is critical to keeping personnel working with energized equipment safe in the occurrence of an arc flash or arc blast hazard. Innovations in arc flash PPE help users to maintain safe practices near energized equipment, reducing the risk of injury, while also providing a more comfortable, easier to use PPE experience. What’s more, these up-dates to arc flash PPE offerings also help protect users from secondary hazards like dehydration and overheating. The greater field of vision offered by some new arc flash face shields also helps users to maintain better visibility while working with energized equipment, thus reducing the risk of accidents and improving safety as well.