Appleton EXGJH and EXLK flexible couplings accommodate vibration, movement and tight bends between sections of rigid metal conduit, preventing damage to the conduit and connected equipment. The modest ‘give’ allowed by these couplings also simplifies installation and alignment where rigid connections are difficult.

Rigid metal conduit, while strong, can’t handle movement well. Appleton EXGJH and EXLK flexible couplings let two conduit sections move independently, unlike those joined by a standard rigid coupling. In difficult bend situations, they can safely be used as an alternative to rigid conduit to navigate around obstacles, corners or other structures. Electrical conductivity is equal to rigid conduit, meaning no external bonding jumper is required. Also, their accurately tapped threads ensure tight, rigid joints while the smooth, rounded integral bushings in each hub prevent damage to conductor insulation.

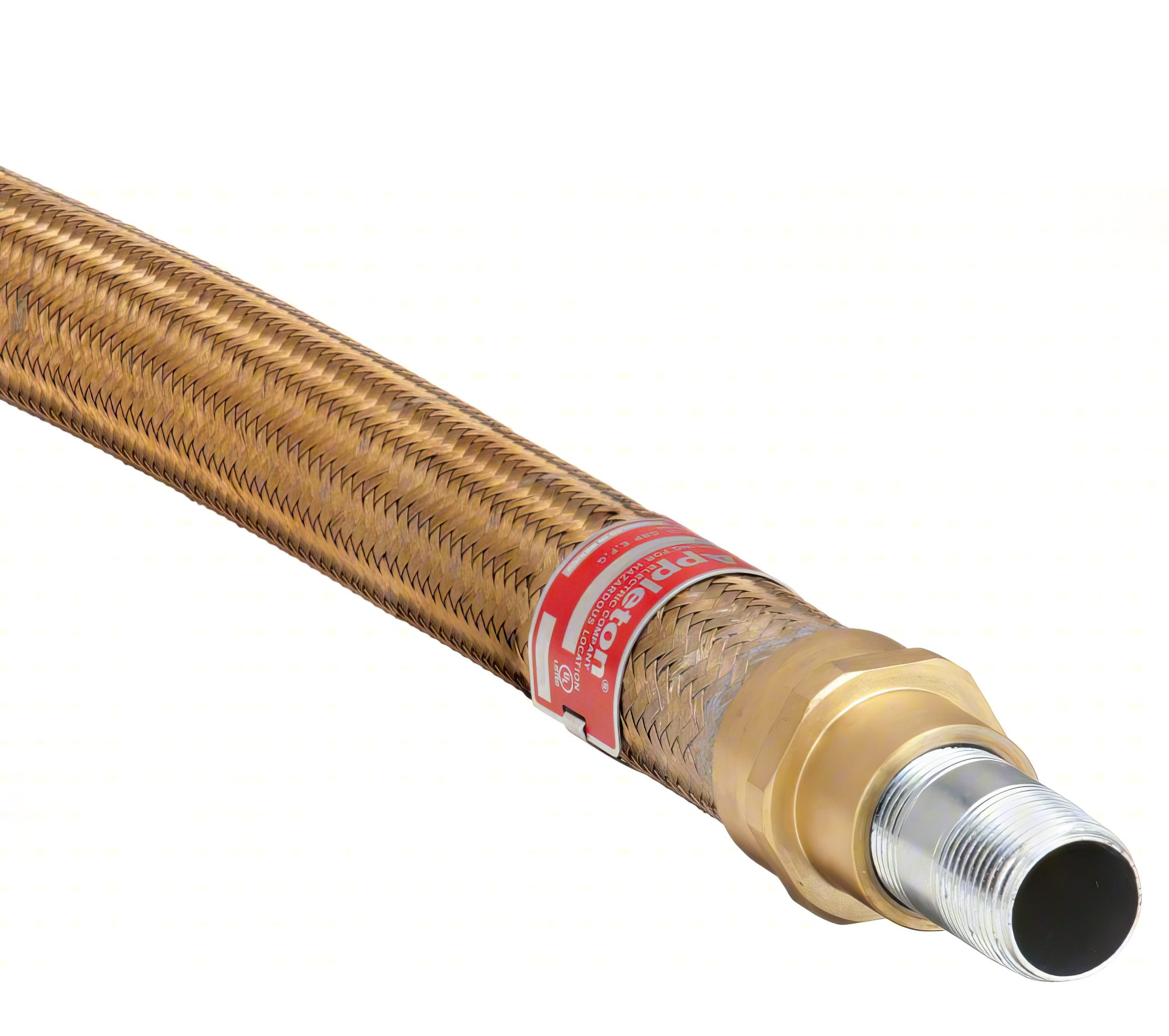

Although flexible, Appleton couplings have a heavy-duty design that resists mechanical abuse with a strong inner core and an insulating liner that protects wires from vibration-induced abrasion. The couplings are certified for NEC/CEC Class I, Division 2 (CID2) hazardous locations, qualifying them for areas where volatile flammable liquids, dusts or gases are handled, processed or used. Being waterproof, the couplings are also suitable for wet locations.

To meet the widest range of demands, Appleton flexible couplings come in lengths from 4” to 36” and diameter sizes of 1/2” to 2” for versions with an outer bronze braid or 2-1/2” to 4” for models with an outer stainless steel braid. The EXGJH version has two female end fittings with male nipples, while the EXLK has a one male nipple and one removal union. Some versions also meet ATEX Certifications and Compliances.

For more information, visit www.appletonelec.com