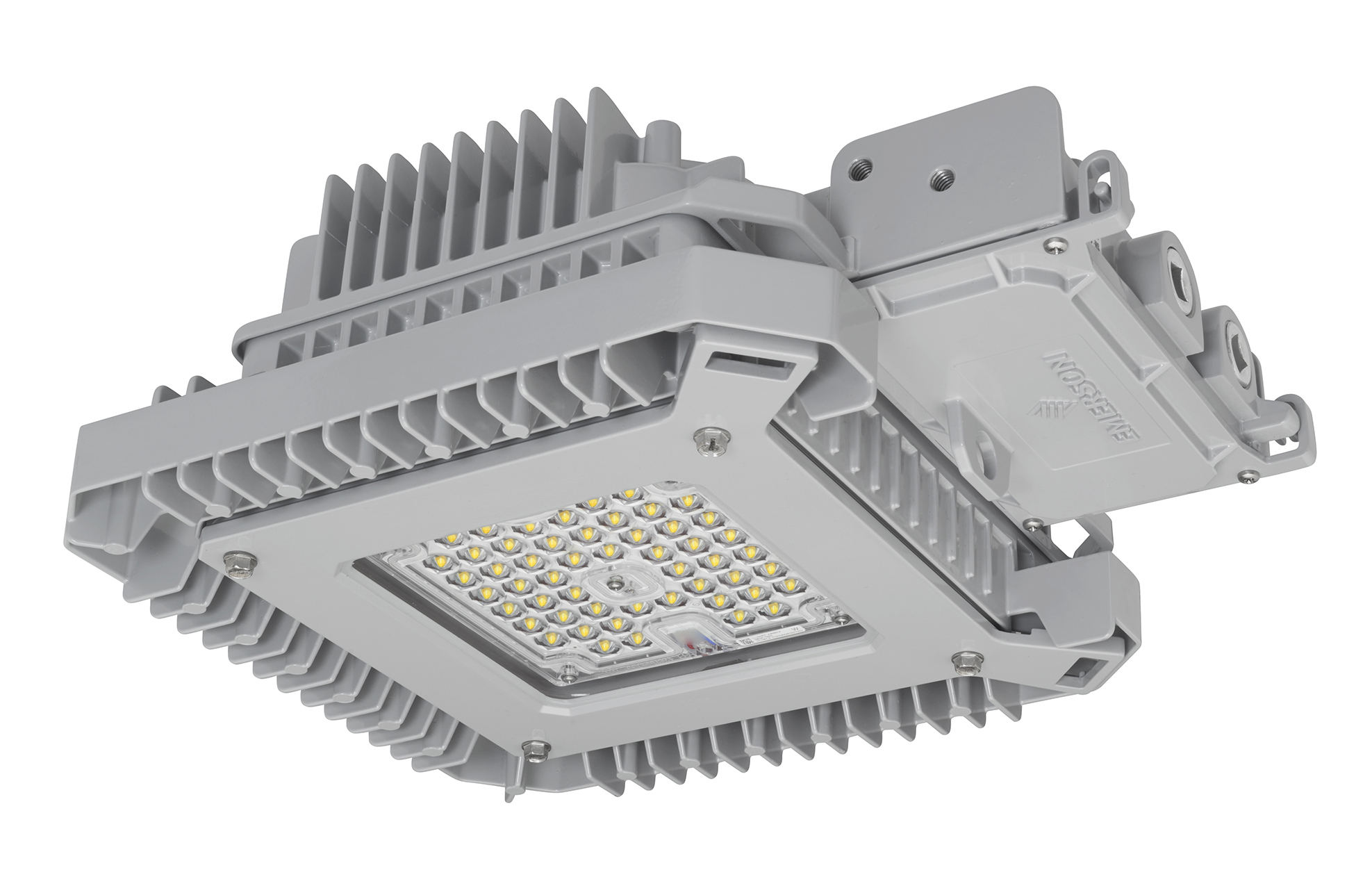

By retrofitting HID high-bays with Emerson’s Appleton Baymaster LED High-Bay luminaires, an industrial facility can reduce its energy costs approximately 65 percent, as well as lower maintenance and replacement expenses, while improving assembly accuracy and potentially speed up assembly operations. A few of the demanding sites where the luminaires excel are power plants, chemical plants, oil refineries, foundries, and wastewater treatment centers.

Emerson designed the Appleton Baymaster LED with the understanding that replacing traditional HID or flourescent high-bays with LED technology can be costly and difficult, especially in harsh industrial and Class I, Division 2 hazardous locations. Because industrial high-bay luminaries are heavy and often in hard-to-reach locations, two or more electricians are required to perform installations, leading to increased labor costs. This installation expense slows return on a company’s LED retrofit investment.

In contrast, the Appleton Baymaster significantly reduces labor costs with its low weight and patented Quick-Mount pendant system. One electrician using standard tools is all that is required to pre-wire the mounting hood, line the arrows up, and lock the Baymaster into place.

Since reliability is the key to lower maintenance costs, Emerson gave the luminaire unprecedented resistance to corrosion, vibration, surges, thermal shock, and moisture. Mounting hoods and bodies are forged from copper-free aluminum protected by a baked epoxy-clad finish, electrostatically applied for complete uniform protection. The result is an industrial LED rated for 84,000 hours with a service life that can exceed 200,000 hours depending on ambient temperature. The robust enclosed, gasketed design ensures safe usage in hazardous areas where flammable gases and vapors may be present, or where dirt, dust, severe weather conditions, and high temperatures are encountered.

Appleton Baymaster LED and Baymaster HL LED luminaires offer 9K, 15K, 19K, 24K, 30K and 38K lumen levels in two color temperatures and three NEMA beam patterns. The luminaires can improve employee vision and alertness as well as reduce shadowing and improve color recognition during the assembly process.

For more information, visit www.emerson.com