Even when transients do not lead to equipment failure, they can still be disruptive causing computers to crash and lose data, for example, process control systems to shut down unexpectedly and cause ground fault current devices (GFCIs) to trip for no obvious reason.

A wide range of measures are available for providing protection against transients, and selection of the most appropriate type must take into account the voltage, duration and power level of the transients, and the type of equipment that is to be protected. Some types of equipment, such as motors may be designed to withstand transients on a typical supply system without further protection, but this should never be taken for granted. Electronic equipment may also feature integral protection, but this is unlikely to be adequate on its own if no other form of protection is installed on the distribution system of the premises in which it is being used.

It may at first seem unnecessary to provide transient protection for test equipment like multimeters and power analyzers but, in reality, such protection is essential. An electrical installation is just as likely to experience transients while tests are being carried out as at any other time and if the energy released as a result of the transient is enough to destroy an unprotected instrument, the user, who is likely to be close to it or even holding it, may well be injured or worse.

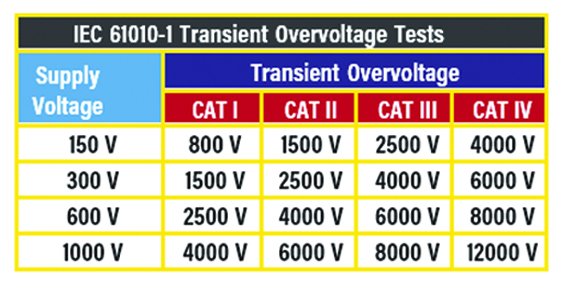

The need for transient protection in instruments is reflected in the international electrical standard IEC 61010 entitled “Safety requirements for electrical equipment for measurement, control, and laboratory use”. This requires test equipment to be able to withstand levels of transients appropriate to the point in the installation where the instrument will be used. (See table)

IEC 61010 recognizes that externally generated transients will be at their most severe at the point where the supply enters the building and will gradually reduce in magnitude as they travel through the electrical installation, because of the inductance, capacitance and resistance of the wiring and other equipment. Put simply, this means that instruments connected at the point of supply need to be able to withstand transient voltages higher than instruments designed to be connected to fixed wiring within the installation, which in turn need to be able to withstand higher transient voltages than instruments that will be used solely on equipment plugged into outlets. This is summarized in the category (CAT) ratings shown in the table.

CAT I rated instruments can be used for measurements performed on secondary circuits not directly connected to main power. This category is rarely used today. CAT II instruments are suitable for measurements performed on equipment connected to a standard 120/240v power outlets.

CAT III instruments are suitable for measurements performed on the fixed wiring within a building installation, typically near the point of entry which includes distribution panels, circuit breakers, bus-bars, junction boxes and industrial equipment.

CAT IV instruments can be used for measurements performed at the source of the low voltage installation which is generally on the utility company side of the meter.

Since instruments with a particular category rating can also be used in lower category applications – a CAT IV instrument can be used in any location within a low-voltage installation – it is often worthwhile investing in instruments with a high CAT rating since this will reduce the risk of an unsuitable instrument being used to carry out a particular task.

Transients can be mitigated using surge protection devices (SPDs), which are designed to prevent voltage spikes and surges damaging the installation wiring, infrastructure and equipment. If an overvoltage occurs, the SPD diverts the resulting excess current flow to earth and limits the voltage to a predetermined maximum value. Depending on circumstances, SPDs can be installed close to the internal source of the transients or close to the loads that need protection, or both.

Three types of SPD are currently available. Type 1 SPDs can discharge partial lightning currents and are used in buildings that are supplied via overhead lines or that have a roof-mounted lightning protection system. Type 2 SPDs are suitable for use in all other types of installation and are often installed at the incoming supply point and/or in sub-distribution panels. Type 3 SPDs have a low discharge capacity and are used to provide localized protection for sensitive equipment. Much more detailed information on the selection and application of SPDs is available on the manufacturers’ websites and reference should also be made to the latest edition of the NEC standards. See NEC article 285.

To decide whether your installation is experiencing problems created by transients, the first action is to use a power quality analyzer and, since transients are almost always intermittent, this needs to be equipped with data logging functionality so that recordings can be made over appropriately long periods of time. A good analyzer will allow limits and alarms to be set to alert you when a significant transient has been detected, you can then examine the data stored by the instrument to gain further information about the form and duration of the transient. This information is invaluable in determining the source.