INSULATION RESISTANCE TESTING has evolved over several decades. The fundamental principles of testing insulation resistance have not varied significantly over that time, however, the instrumentation used to measure insulation resistance has improved greatly in capability, accuracy, functionality and usability. Insulation resistance test instruments resistance testers are commonly known as Megohmmeters.

One interesting common belief is that these instruments, in fact, measure resistance. They do not. Insulation resistance testers actually measure current. They calculate the resistance using ohms law, R=E/I. They can do this because they know the voltage that they inject and can measure the current that flows through the device under test.

Insulation Resistance test is typically classified by the highest voltage level they are able to produce. Common ranges are 500, 1000, 2500, 5000, 10,000, 15,000 and higher. Generally speaking their higher voltage testers are used in more sophisticated applications where other variables like inductive and capacitive elements are present in the device on the test requiring longer test times to achieve effective results.

A quick review of the test process shows that there are 3 currents that are present during an insulation test. These are Capacitive charging current, Absorption current and Conduction current. A proper insulation test requires applying the test voltage long enough such that the capacitive charging currents and absorption currents are stabilized and the remaining current to be measured is the conduction current.

Conduction current, often called leakage current, is the steady current present both through and over the insulation. This is a critical measurement since an increase in conduction current over time is likely an indication of deteriorating or damaged insulation.

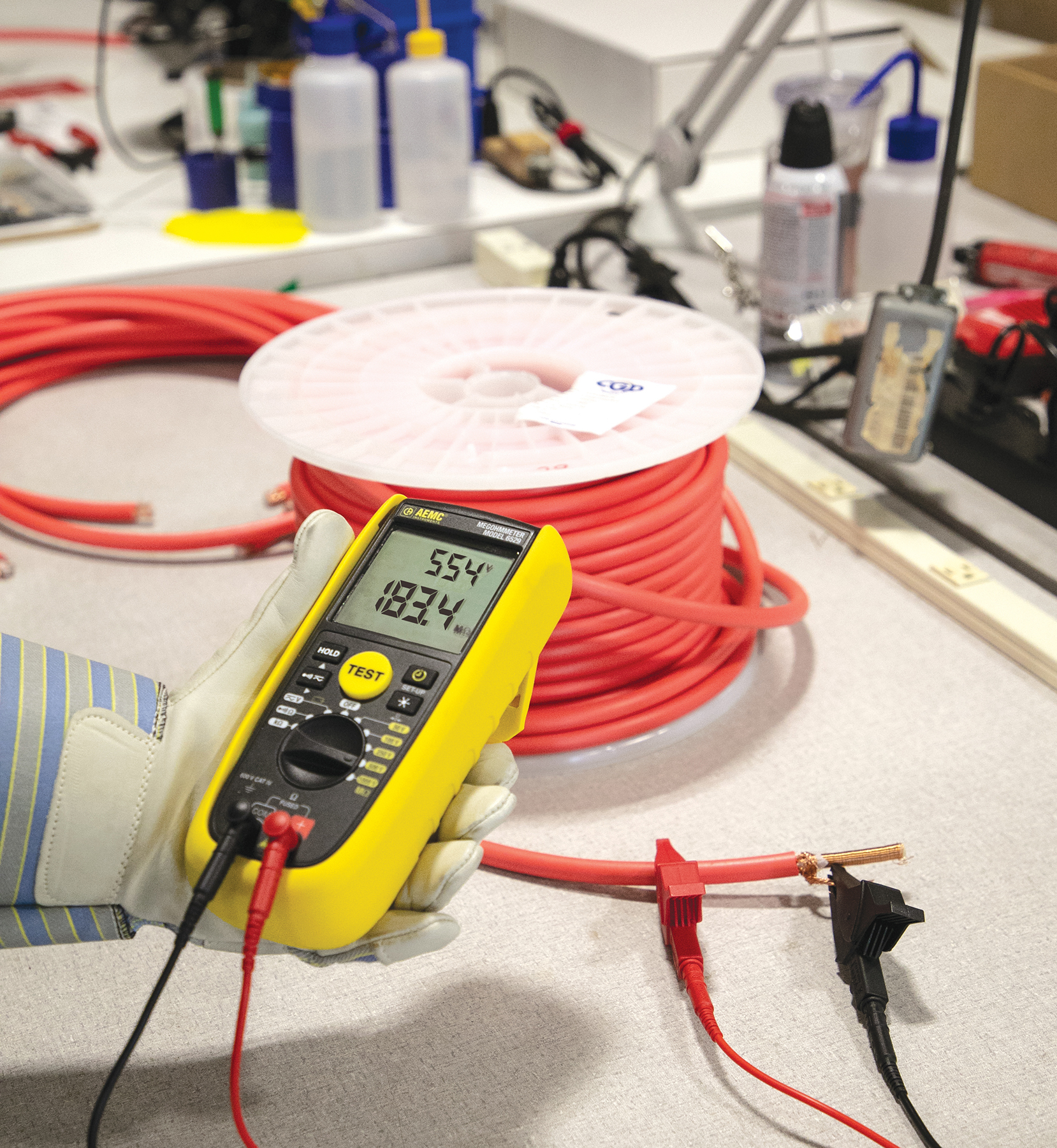

More modern handheld insulation testers today are available with multimeter functions as well as insulation test functions, the AEMC model 6529 pictured here includes this capability.

Large motors, long cables and other devices with appreciable reactive components require longer test times and thus more sophisticated insulation test equipment.

On a day-to-day basis a basic 1000 Volt handheld type insulation tester is a valuable tool to keep in one’s tool bag. These instruments tend to be lower in cost and extremely easy to operate and get quick results testing devices such as power cables and small motors that are fundamentally resistive in nature with little to no inductive properties. The test time requirements in these applications tend to be short, to minutes or less and generally require test voltages of 1000 volts or less for a handheld Megohmmeter.

More modern handheld insulation testers today are available with multi-meter functions as well as insulation test functions AEMC’s model 6529 pictured here includes this capability. Multimeter functions and insulation test functions are clearly identified on the selection switch by color. The white switch positions are multimeter functions, the yellow switch positions are installation test functions making it very easy for the operator to identify. The multimeter functions include a voltage, continuity, and resistance measurement capability. The installation test functions include selectable test voltages of 5100 to 5500 and 1000 volts. This instrument is also capable of running spot checks or time tests. A simple setup function allows selection of the time for testing a whole function. This provides the operator the ability to freeze the display assisting in documenting the test results. A blue electroluminescent backlit display makes this device very easy to use and read in poorly lit areas.

Some of the key features of this device are:

- Selectable test voltages 50, 100, 250, 500 and 1000V

- Basic DMM functions; Volts, Continuity, Resistance

- DAR and PI ratio test functions

- Dual line display to view the insulation value and real-time test voltage simultaneously in an easy-to-read format

- DMR mode – relative resistance comparison to a reference value

- 2-color backlighting easily shows alarm conditions

- Shockproof sheath for excellent handling

- Automatic power-off function to optimize the battery life

- Programmable alarm thresholds

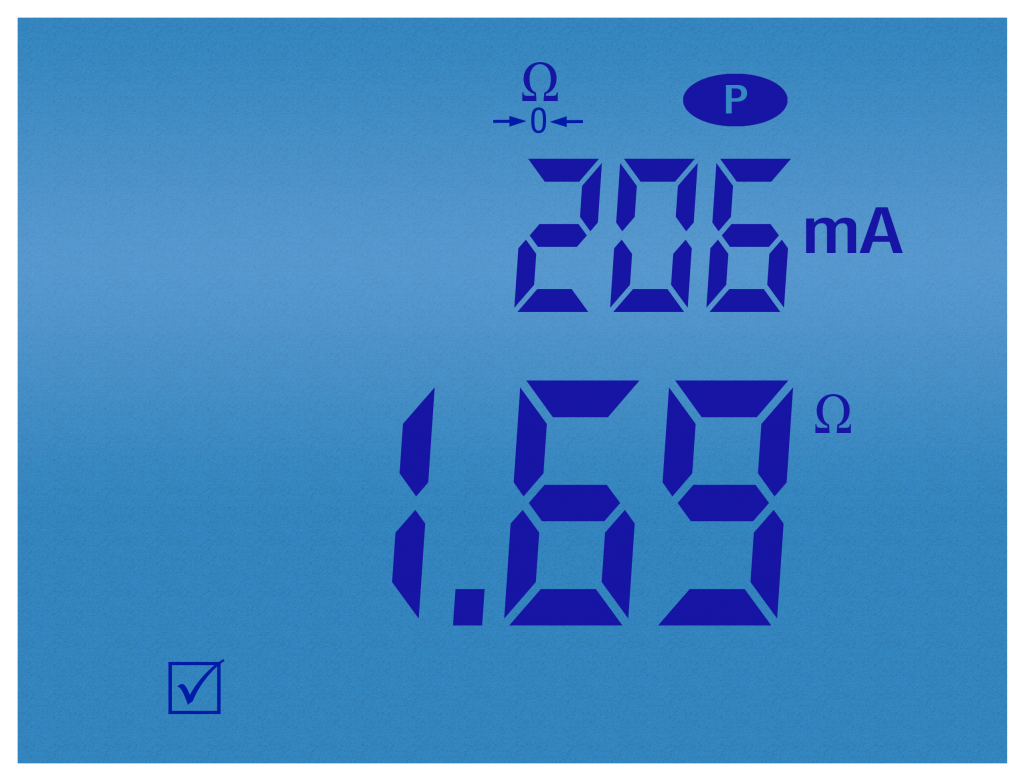

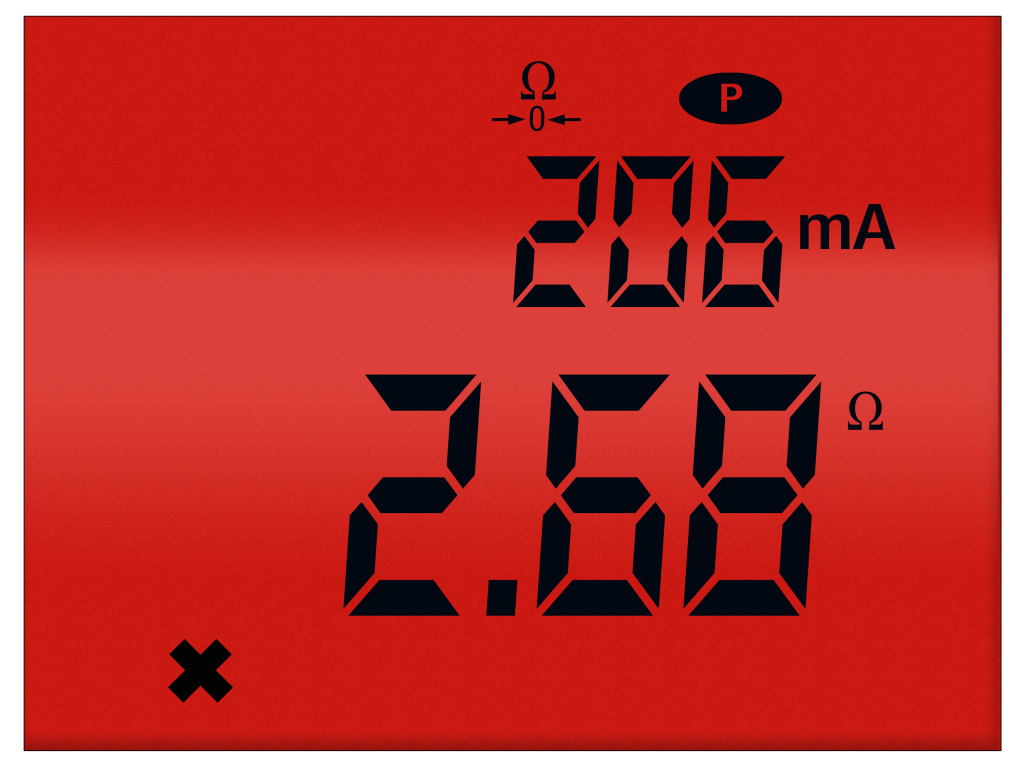

One key feature of the model 6529 is its ability to provide a quick visual of both general resistance and insulation resistance out of tolerance conditions changing the backlight on the display to red. Thus, a quick visual go-no-go decision can be made. Blue display is a go, a red display is a no-go. The display also indicates the test voltage and the resistance reading. As shown below during a resistance test where a reading over 2 ohms would be a faulty condition the display changed from blue to red and activated an alarm buzzer (user selectable) making it quick and easy to assist the operator in identifying the problem.

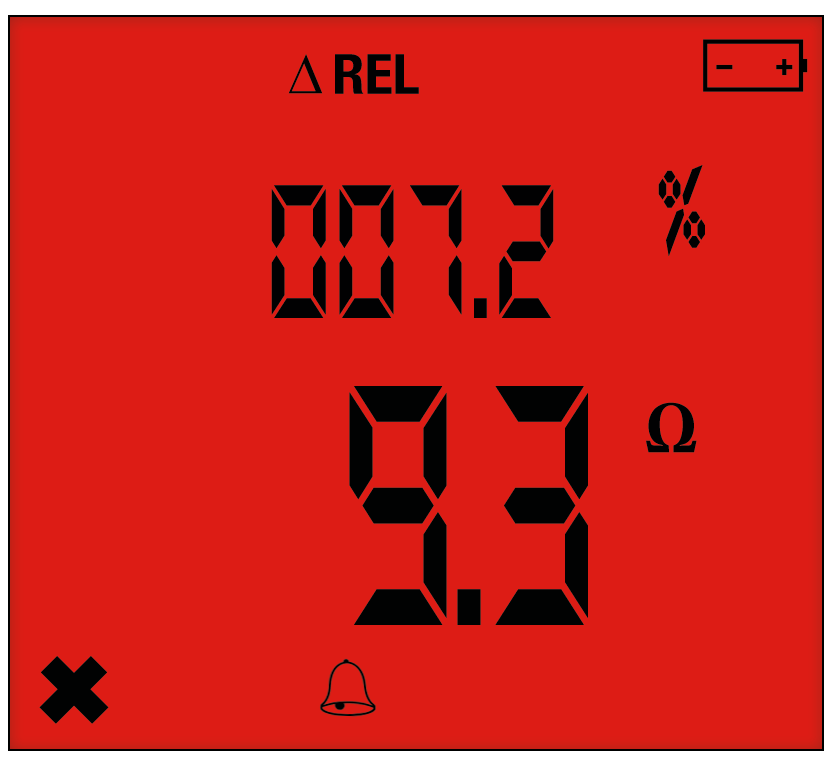

One other key feature of this versatile low-cost Megohmmeter is one called Differential Mode Resistance (DMR).

This is a great asset in verifying that multiple items that should have the same resistance value are within an acceptable range.

Here the operator first measures the resistance of the reference product then presses the test button to lock the reading in as the reference. From there on subsequent measurements are compared to the reference and the delta value is displayed. If the reading is outside of the differential percentage selected by the user and stored using the setup function, the display turns red to indicate a potential defective product as shown here.

Having a low-cost handheld insulation resistance tester in your tool bag will be a valuable and versatile asset when troubleshooting and qualifying material on the job site. It will pay for itself in no time saving you time and cost during typical installations and repair work. The AEMC 6529 is feature-rich and designed for day-to-day electrical installation tasks.