IF YOU OWN OR RUN A BUSINESS, it’s very likely that one of the things you’re least likely to think about on a regular basis is the quality of your electricity. For a start, what is power quality and how can it vary? Surely you can depend upon your energy supplier to look after this sort of thing, and anyway, does power quality really matter or is it just something for specialist engineers to worry about? In this article we’re going to answer those questions, but let’s start off by saying that power quality is most definitely a concern for us all.

Have you ever had a piece of equipment – most likely a computer or other electronic item – that functioned poorly or failed regularly for no apparent reason?

Maybe you have lights that flicker, or if you operate a factory, motors that run hot and fail sooner than expected. All of these could be the results of poor power quality and if you don’t realize this, the time and money you spend on trying to fix the symptoms are likely wasted. Power quality issues can also increase your energy bills, eating further into your hard earned profits.

For these reasons, everyone who owns or runs a business needs to be aware of the basics of power quality, to understand how to assess it, and to know what to do if and when problems are identified. A few minutes spent reading this article could save you a lot of time, trouble and money.

What is Power Quality?

In a perfect world, you would expect your electricity supplier to provide you with an AC supply at a constant voltage, a fixed frequency, and with perfectly sinusoidal waveforms that have no nasty spikes on them. Also, if it is a three-phase supply, you would expect the voltages of the three phases to be exactly the same. This would be perfect power quality. However, as we don’t live in a perfect world, your supply may not actually meet these requirements and even if it does meet them at the point it enters your premises, it may well become degraded as it passes through the electrical installations at your site.

As this suggests, if you have power quality issues, in many cases it’s not the fault of your utility company. The operators do, in fact, go to great lengths to ensure that they deliver clean supplies, but some of the factors that affect supply quality, such as thunderstorms and the equipment you’ve got installed in your own premises, are beyond their control.

That said, what can possibly go wrong with power quality? In practice, almost all power quality issues can be divided into six main areas. These are: harmonics, sags and surges, transients (spikes), interference, voltage imbalance and poor power factor. Let’s examine each of these issues.

Harmonics

In an ideal power system, voltage and current waveforms would be perfectly sinusoidal. This would not be too difficult to achieve if all the loads connected to the power system were linear – that is, the loads where the current drawn from the supply is always proportional to the applied voltage. Basic heaters and incandescent lighting are examples of linear loads and, until the last few decades of the 20th century, loads were predominantly of this type.

Within the last 30 years, however, there has been a big increase in the number of non-linear loads connected to the electrical network. These include computers, uninterruptable power supplies, variable speed motor drives, electronic lighting ballasts and LED lighting, to name a few. The growing use of such equipment, and the use of electronics to control nearly all types of electrical loads, have an effect on the electricity supply and on individual site installations. It is estimated that today over 95% of the harmonics present on a given site are generated by equipment installed at that site.

As we have stated, when a linear load is connected to the supply it draws a sinusoidal current at the same frequency as the voltage. Non-linear loads, however, draw currents that are not necessarily sinusoidal. In fact, the current waveform can become quite complex, depending on the type of load and its interaction with other components in the installation. Non-linear loads produce distorted current waveforms in the supply system, and in severe cases this can result in noticeably distorted voltage waveforms. The consequences can include significant energy losses, shortened equipment life and reduced operating efficiencies of devices.

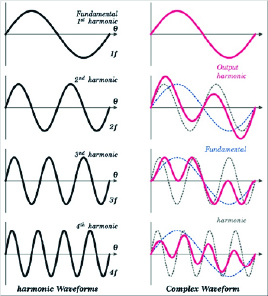

The distortion of the waveform produced by non-linear loads is equivalent to adding components at integer multiples of the supply frequency to the pure supply frequency waveform.

That is, for a 60 Hz supply, the distortion takes the form of additional components at 120, 180, 240, 300, 360 Hz and so on – an example is shown in Figure 1.

analyzed as multiple sine waves added

together

These additional components are the harmonics, and in theory, they can go all the way up to infinity. In practice, however, it is rarely necessary to consider harmonics above say, the 50th, which has a frequency of 50 x 60 Hz = 3 kHz and, in most cases, only the lower order harmonics, up to the 15th, will be of importance. Unfortunately, unless they are prevented from doing so, harmonics from a non-linear load will propagate through the supply system causing problems elsewhere.

Knowing that a distorted current waveform can always be represented as a series of superimposed sine waves (using a mathematical procedure known as Fourier analysis) makes it possible to devise a measure of the amount of harmonic distortion present in the current in a supply system. This is known as total harmonic distortion (THD).

Harmonic currents have negative effects on almost all items connected to an electrical system; they upset sensitive electronic devices, they increase heating, and they produce mechanical stresses. Among the most common effects of harmonics are computers crashing, lights flickering, electronic components failing in process control equipment, problems when switching large loads, overheating of neutral conductors, unnecessary circuit breaker tripping and inaccurate metering.